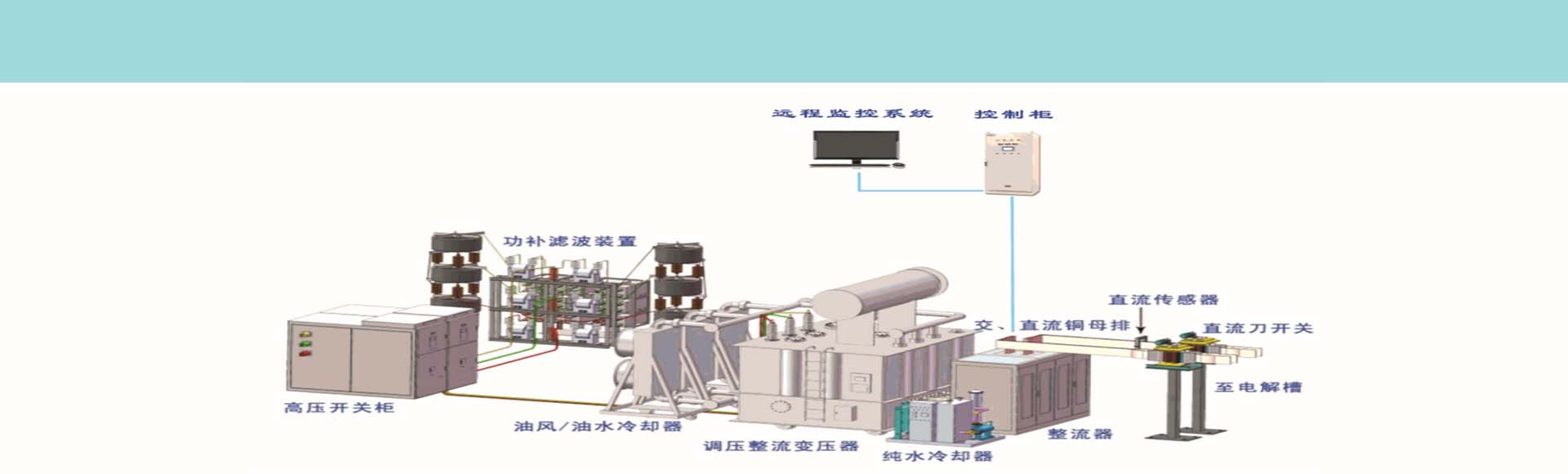

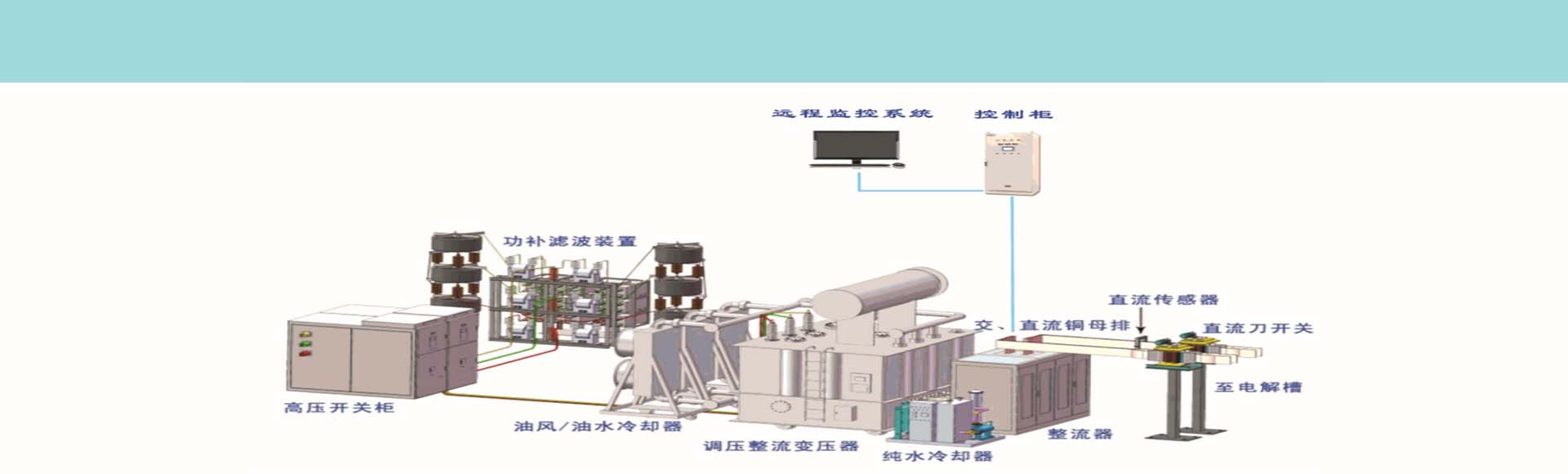

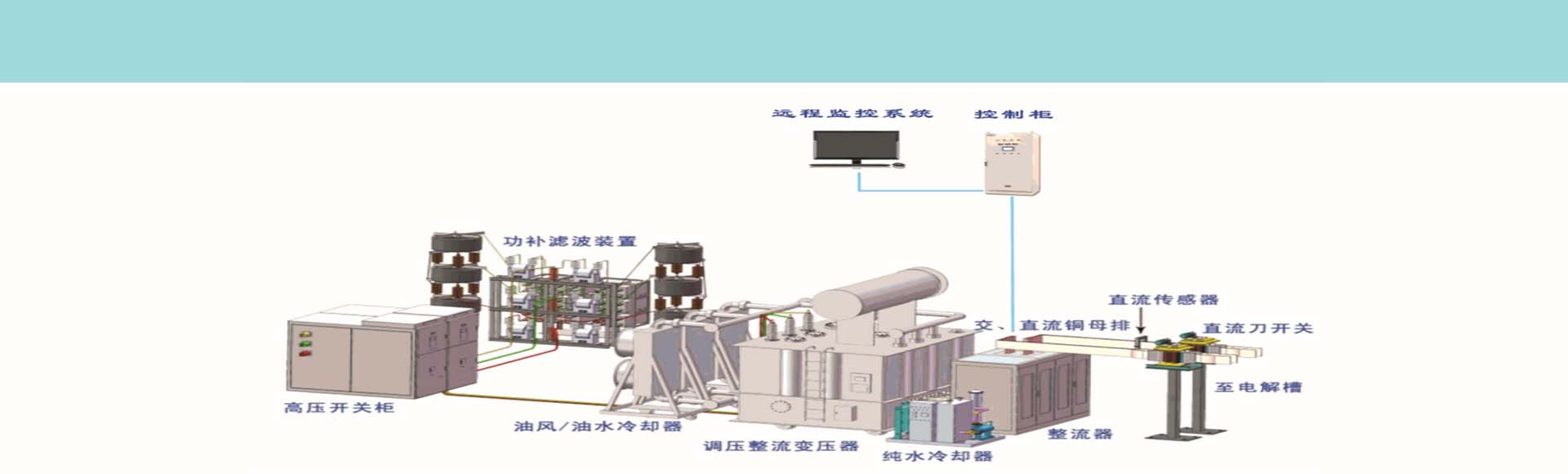

Product Overview:

This product is designed for high-power rectification systems in industries such as chemical processing, metallurgy, military, and scientific research institutes. It is compatible with:

Thyristor-based rectification systems (6-pulse, 12-pulse, or multi-pulse topologies up to 24/48-pulse).

Diode rectifiers with saturable reactors for high-power applications.

Dual-core controller: Combines DSP (Digital Signal Processor) and CPLD (Complex Programmable Logic Device) with PLC integration.

High reliability: Supports dual-channel hot redundancy backup for critical operations.

32-bit DSP: Achieves current stabilization accuracy ≤0.1% and μs-level response speed.

Flexible operation modes:

Constant Current (CC)

Constant Voltage (CV)

Constant Power (CP)

CPLD-driven pulse generation:

Control angle resolution: <0.1°

Regulation accuracy: ±0.5%

Implements hardware-equivalent logic via software for ultra-high reliability.

Key performance:

Control angle resolution: <0.1°

Regulation accuracy: ±0.5%

Frequency Adaptive Technology: Automatically synchronizes with grid fluctuations.

Dual feedback redundancy: AC/DC feedback signals operate in mutual backup mode.

Advanced protections:

Soft start | Anti-flicker power recovery | Data backup

Fault self-diagnosis (supports real-time alarm codes).

Hybrid trigger system:

Optical fiber (for EMI immunity)

Electrical pulse (cost-effective)

Selectable via software based on project requirements.

Remote monitoring: Real-time data logging and AI-driven fault analysis.

Multi-protocol support:

Fieldbus: Profibus, Modbus RTU

Industrial Ethernet: Profinet, EtherCAT

IoT-enabled: Wireless data transmission via 4G/5G or Wi-Fi.

Mobile APP:

Platforms: Android & iOS

Functions: Real-time status visualization, alarm push notifications, historical data export.

| TYPE | Specification |

| Operating Power Supply | 380VAC/220VAC/110VAC/110VDC |

| Synchronization Power Supply | 220VAC,50Hz/110VAC,50Hz |

| Pulse Trigger Types | Dual-Narrow Pulse /PWMAdjustable Pulse |

| Pulse Characteristics | Pulse Leading Edge <1us,Pulse Asymmetry <0.1° |

| Voltage Regulation Accuracy | Exceeds+0.2% |

| Communication Protocols | Profibus-DP、Modbus、Industrial Ethernet |

| IP Rating | IP42、IP54、IP55 |