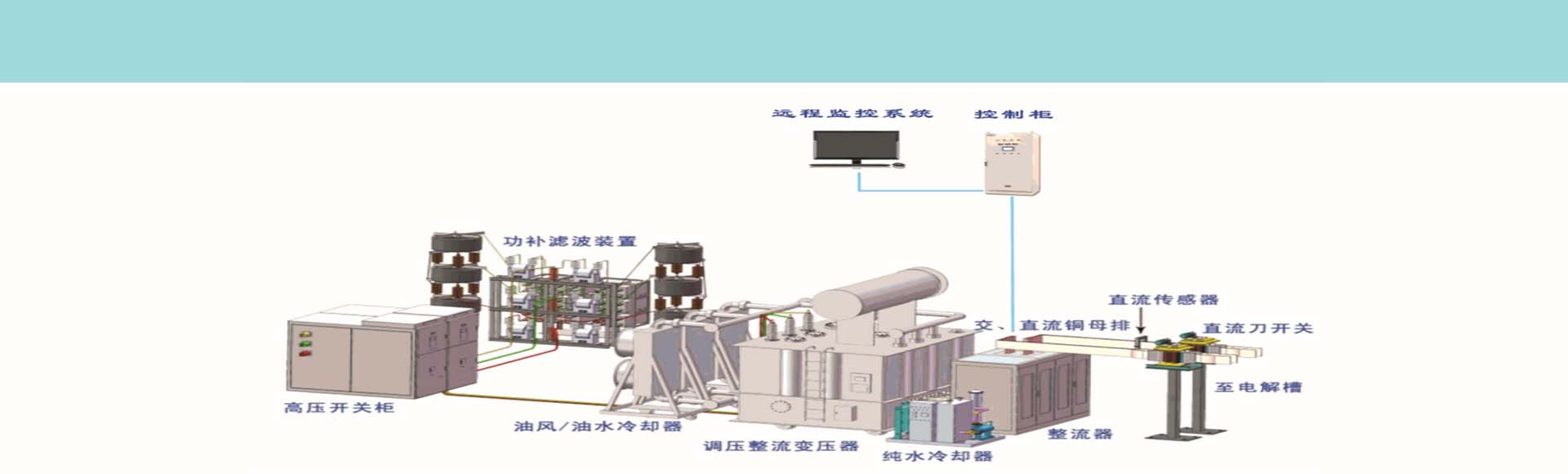

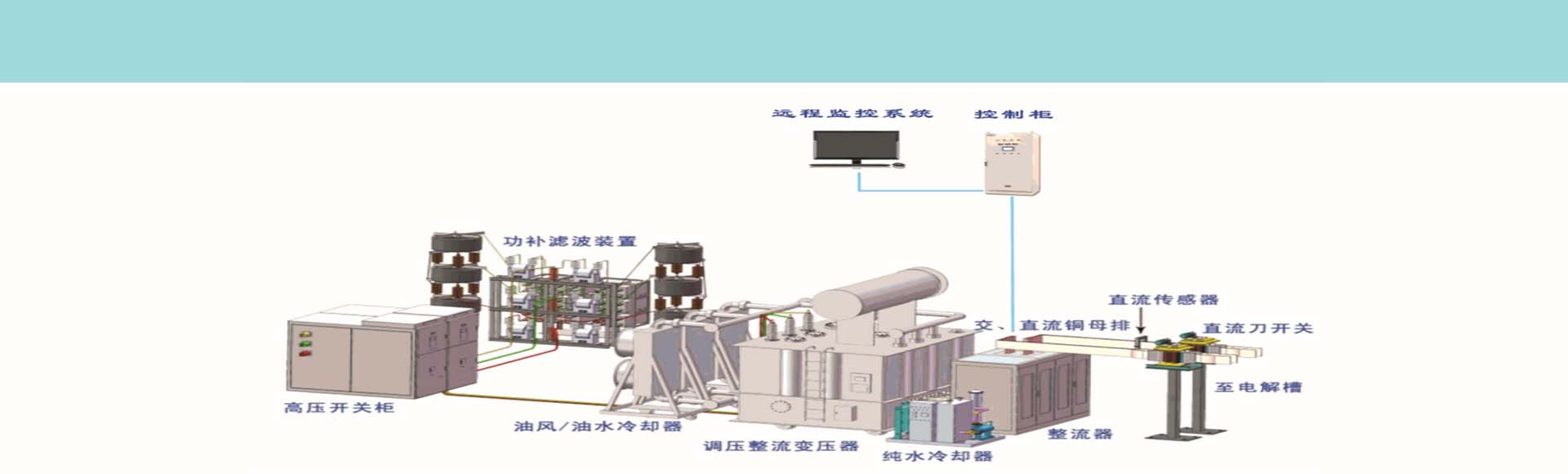

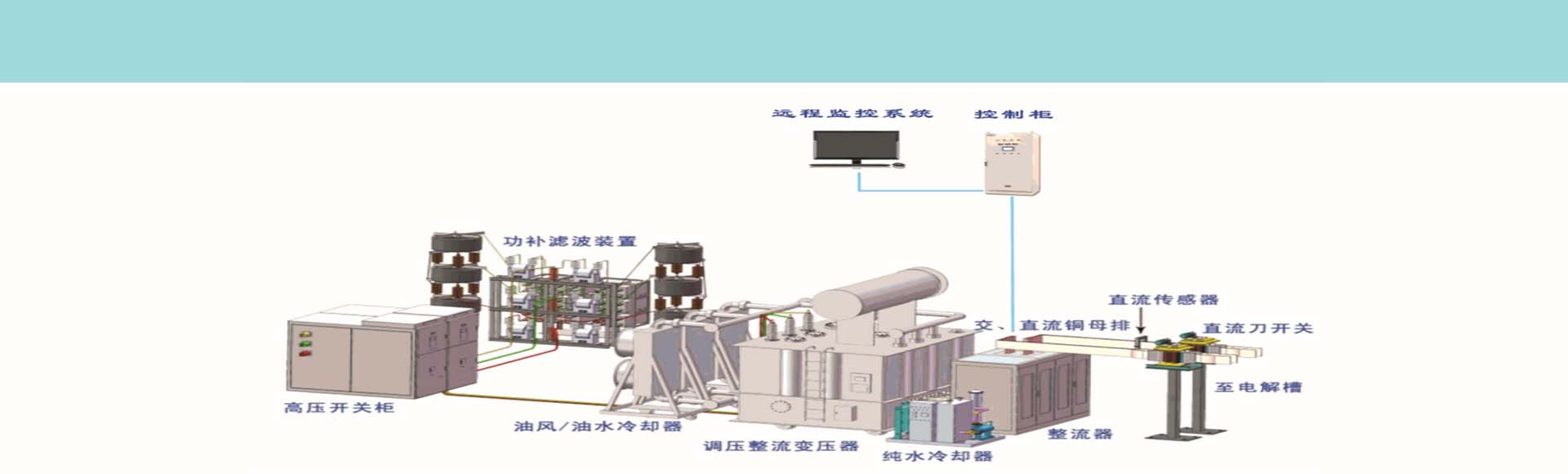

This high-power rectifier is widely used in metallurgical, chemical, papermaking, graphite, and military industries, providing DC power for electrolysis processes of aluminum, zinc, copper, magnesium, sodium, lead, manganese, caustic soda, chlorine dioxide, etc. It also serves as a heating power supply for DC arc furnaces, graphitization furnaces, mineral smelting furnaces, steel wire heating, and high-voltage transmission line de-icing.

Low Vibration & Noise Design

Conductive busbars inside the rectifier cabinet are insulated with epoxy-coated I-beams, ensuring minimal vibration and noise.

Enhanced Insulation Performance

Internal busbars are supported by high-strength epoxy resin boards, significantly improving insulation reliability.

High-Efficiency Cooling System

Rectifier components utilize single-press-formed copper heat sinks, ensuring optimal contact with uniform surface pressure, reducing contact resistance and component loss.

Isolated Overvoltage Protection

Over-voltage protection devices are physically isolated from the main circuit, preventing main cabinet failures caused by protection device damage and enhancing safety.

Space-Saving Integrated Design

The rectifier system supports integrated modular packaging, combining the main rectifier cabinet, control cabinet, distribution cabinet, DC disconnect switch, and pure water cooler into a single sealed container. This reduces footprint and prevents dust ingress.

Adaptability to Extreme Environments

For Arctic or extreme heat regions, an adaptive thermal management system is optional, including built-in air conditioning and thermal insulation layers. This maintains a constant internal temperature regardless of external conditions.

Product Parameters

Installation Method

| Parameter types | Parameter |

| Maximum Output DC Voltage | 2kV |

| Maximum Output DC Current | 150KA |

| Installation Method | Indoor / Outdoor |

| Main Circuit | Three-Phase Bridge /Double Inverse Star |

| Rectifier Elements | Silicon Controlled Rectifier/Diode |

| Number of Pulses per Cabinet | 6/12/24 |

| Cooling Method | Water Cooling / Air Cooling |

| Protection Configuration | Commutation Overvoltage、Switching Overvoltage、Low Water Pressure、High Water Temperature、High Bridge Arm Temperature |

| Protection Rating | IP40 / IP42 / IP55 |